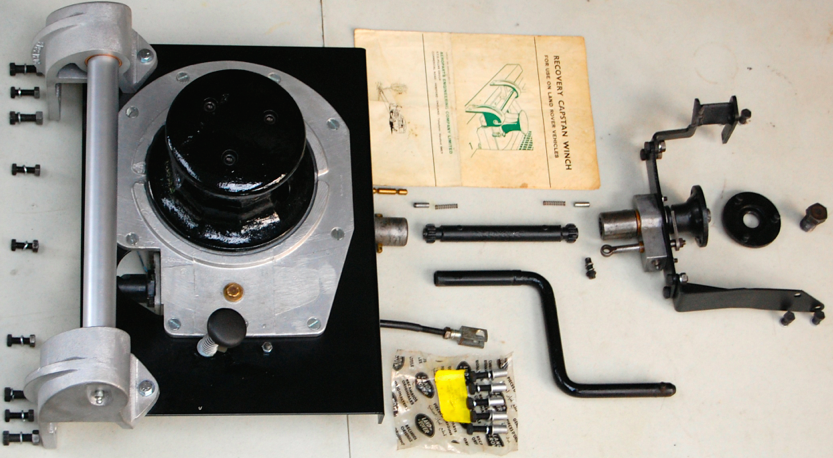

Aeroparts Capstan Winch

With the introduction of the Land Rover Series II, the AEH.D.**** type winch remained in production virtually unchanged. The baseplate changed dimensions again to suit the Series II chassis and there were a number of very minor and short-lived design variations to a few of the drive shaft components. The 2l Diesel driveshaft assembly was retained for use with the new 2,286cc petrol engine. There were however, a number of different variations of the driveshaft support brackets, including a universal set for both the 2l IOE and 2,286cc engines and a special bracket for use when an Iso-speedic engine governor was fitted. By the late 60’s, the line pull was increased by 500lb to 3000lb. AEH.D.**** winches are the most common of the Aeroparts capstan winches and remained in production right up to the beginning of the 1970’s. In 1970, winches were no longer fitted by the factory, but outsourced to Spencer Abbott. I have estimated a total of around15,000 AEH.V.**** and AEH.D.**** winches were manufactured from 1950 to 1971.

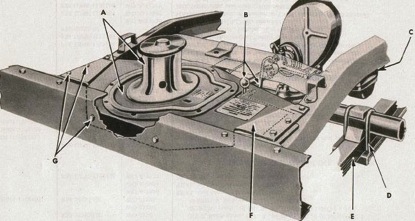

With the

introduction of the Series III, came the next significant design change.

The most obvious was the introduction of the ‘small bollard’. The bollard

was now a one-piece casting with an exposed single bollard shaft bolt. The top

of the bollard was dished and a small drain hole was drilled in the side of it.

The other major design change was a critical safety modification that had been

lacking in the Aeroparts design since the rear capstan winch. From November

1971, the mills pin used to fix the worm gear to the driveshaft was

replaced with a brass shear pin designed to shear when a load of 3000lb was

exceeded. This driveshaft pin would sheer before the pin in the bollard,

allowing the winch to fail safe rather than the bollard spin uncontrollably on

the shaft. This design change may have been a direct response to the

Mayflower capstan winch released two years previously. To allow the new shear

pin to be changed quickly or a bolt to be inserted for hand cranking the engine,

the gear casing and the base plate were cut to allow easy access to the shear

pin from above. In 1973, the attractive aluminium fairlead castings,

which had been used since 1950, were replaced with simple folded steel brackets

often painted red. The fairlead roller was now hollow and ran on fibre bushes

rather than bronze bushes. The first generation of small bollard winches were

stamped AEH/FW.*****.3

The final Aeroparts capstan variation, known by its Unipart part number as GLR101, was introduced in 1976 costing £126.60. The dish in the top of the bollard was now covered with a thin metal plate. There was no longer a drainage hole in the bollard and the driveshaft was redesigned to a system similar to the Fairey capstan winch. Very late winches had a modified gear wheel with a steel inner and a bronze outer, unlike the earlier solid bronze gears. The winches were no longer stamped with a serial number but had a small green information plate stuck to them instead.

Above: Late 'small bollard' GLR101 Aeroparts Capstan winch with simplified driveshaft

Aeroparts adapted their

design to meet the requirements of the General Post Office (GPO) and later

British Telecom (BT). They inserted an extension piece between the bollard cap

and the main bollard casting. This resulted in the ‘tall bollard’ winch. The

GPO used the capstan winch primarily for pulling cable below ground and the cast

alloy fairlead brackets were attached to the bumper so they protruded in front

of the vehicle with the rope passing over the top of it. Like the small bollard

winch, the cast aluminium fairlead was later replaced with a simpler fairlead

unique to the GPO. The tall bollard was required to give the appropriate angle

for the rope to naturally pass over the bumper fairlead and towards the ground,

it was not for putting more turns of rope on the bollard, as this could easily

damage the winch with the increase in leverage on the bollard. The tall bollard remained in production

alongside the small bollard winch eventually adopting the simpler driveshaft

mechanism. Another adaptation for the GPO was the conversion of Aeroparts GLR104

hydraulic drum winch into a capstan winch. It used the same bollard design as

the mechanical capstan winch, but used the gearbox from the GLR104 hydraulic

drum winch as its power source, however this is beyond the scope of this

article.

After the war, Aeroparts had

to adapt to the new world, just like Rover and began diversifying into new

unfamiliar markets. By the late 1960’s Aeroparts were already a part of the

RTZ-Pillar Group and were later owned by the mining giant Rio Tinto. Finally in

1986 Aeroparts merged with Peak Engineering. This last merger and increased

competition from Fairey was the final chapter for Aeroparts and the Aeroparts

factory is now a supermarket car park!