MAP / Fairey Capstan

In 1969, Mayflower Automotive Products (MAP) of Tavistock, Devon introduced a new Capstan Winch to compliment their existing range of Land Rover approved optional equipment. MAP had already achieved success with the Mayflower mk3 mechanical drum winch and Free Wheeling Hubs, which were approved a few years earlier. Since 1950, the only approved capstan winch was the Aeroparts winch. The new capstan winch design was undergoing type approval in April 1969 by the Special Projects Dept and was displayed to the public at the ‘Rovershow’ near Northampton.

The major

design difference between the Aeroparts and MAP winch was the driveshaft mechanism

and the worm gear layout. The winch input shaft that carried the worm gear was

not an integral part of the gear and could slide within it. Drive was

transmitted from the input shaft to the worm gear via a key-way. This design

allowed for a much simpler driveshaft to be used, made of fewer and less

complicated parts, compared to the Aeroparts design. Importantly, it was the first

capstan winch to fit both the 4 cylinder and 6 cylinder engine without the need

for any modification or additional components.

Other differences included the method of lubrication of the bollard

shaft bushes, using splash lubrication rather than grease as in the Aeroparts type

and the addition of a shear pin within the drive shaft mechanism to allow the

winch to fail safe, if the 2500lb line pull was exceeded, an idea that was

copied by Aeroparts a few years later.

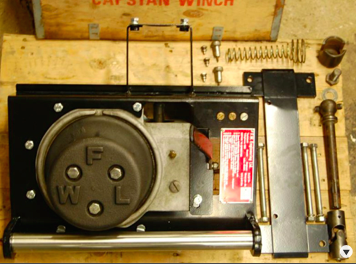

To engage

the winch, the lever at the side of the bollard was moved into the forward

position. This moved the driveshaft towards the engine. The shaft, supported by

a bracket and large conical spring, engaged into a simple drive dog, which replaced

the starter dog on the engine crankshaft. To aid lining up the driveshaft and

the dog, a short starting handle was supplied. This was inserted into the

winches own starter dog.

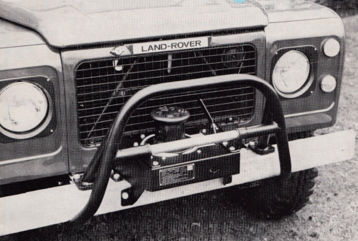

A very early advert for the ‘new’ MAP Capstan Winch shows an Aeroparts gear casing with a modified fairlead and selector mechanism. It is quite possible this winch was a prototype or ‘mule’ for the production version, using many Aeroparts winch components.

A very early MAP capstan winch with early shaped bollard

The first

few hundred MAP capstan winches had a bollard design similar to the Aeroparts,

but with a flat cap with the head of the securing bolts raised and M.A.P cast

into the top. Somewhere between winch serial number 200 & 400, the bollard

was redesigned to the more recognizable ribbed type with the head of the

securing bolts sunk into the bollard cap. MAP was still cast into the top of

the bollard but the letters were now bold. This bollard design was used up to

the end of production in the 1980’s.

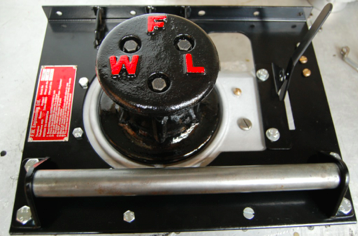

In 1971, Fairey bought MAP and continued to manufacture many of the MAP designs. The capstan winch underwent a number of modifications including replacing the lettering on top of the bollard to FWL (Fairey Winches Ltd) and a modified input shaft to accept the new driveshaft UJ with new screw-in shear pin. The new UJ was shorter than the old MAP knuckle type and the driveshaft was extended accordingly. The diameter of the fairlead roller was reduced and was now made from a solid bar rather than a hollow tube found on the earlier MAP winch. The base plate gained 3 threaded holes to store the spare shear pins and one of the front base plate mounting bolts was replaced with a counter-sunk set screw to stop the rope snagging on the bolt head as it passed through the fair lead. These modifications increased the line pull to 3,100lb, 100lb greater than the rival Aeroparts winch.

3000lb Fairey winch

In 1978, the line pull of the Fairey capstan winch was increased from 3100lb to 4000lb. This was achieved by the addition of a bronze bush in the winch sump plate and a longer bollard shaft. A new larger diameter shear pin was also introduced at this point. On the standard Land Rover winch, the baseplate was strengthened with the addition of a number of gussets welded to the fold at the back of the plate.

Fairey Capstan Winch for Range Rover Classic

When the

Range Rover was released in 1971, Fairey were quick to capitalize and

adapted their capstan winch to suit. A new baseplate, driveshaft support

bracket and drive dog to fit the V8 engine was introduced, however the

actual winch unit remained virtually unchanged. To retain the

upmarket image of the Range Rover, Fairey marketed the capstan winch with a

chrome fairlead roller, rather than a galvanized one supplied with the Land

Rover version. The winch could be neatly hidden behind the front grill when not

in use. Quick release fasteners were supplied with the kit to allow for the

easy removal of the grill. This winch was fitted to the famous Darien Gap

Expedition Range Rovers.

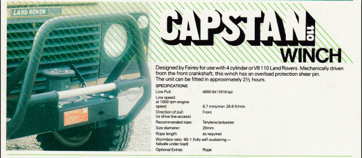

Fairey Capstan Winch for Stage 1 V8 & 90/110

The next new

Land Rover came in the form of the Land Rover Series 3 Stage 1. Once again,

Fairey were quick to adapt their winch to suit. Another new base plate was

designed and an ingenious bull-bar come mounting bracket was developed. It was

another neat solution.

The Stage

1 V8 design was carried forward and once again adapted for use with the Land

Rover 90 / 110 4 cylinders and V8 models.

The final

chapter of the Mayflower Capstan Winch story begins with American winch

giant, Superwinch buying FWL in 1985. Superwinch carried on producing the

capstan winch for a short period before finally discontinuing the winch from

their range. The ‘Superwinch’ capstans usually do not have any lettering on the

bollard.

Fairey

‘specials’

Just like

Aeroparts, Fairey identified a market for organizations that used winches for a

very specific task. One organization Fairey focused on was the Coast Guard. And

designed a bollard with a smooth round surface to aid control of the rope while

performing cliff rescue. These winches are very easily identified as they have

‘Fairey Winch CG’ cast into the top. The fairlead is also a different design to

the standard winch and can be unlocked and lifted up to allow the rope to be

placed around the bollard, rather than having to thread the rope through

the fairlead, before wrapping it around the bollard.

Manufactured

for around 20 years and by 3 companies the Mayflower designed capstan winch has

stood the test of time well and is still a popular and sought after accessory

today.

Never miss an offer. Ever.